Metalexpert

News

Discover the latest exhibitions, events, and news in the metal industry

Japan's Nippon Steel said on Thursday that it had extended the closing period for its planned purchase of U.S. Steel, worth nearly $15 billion. The company expressed confidence that the acquisition will protect and grow the American company despite the impasse in the United States.

A mining technology startup in Newark, New Jersey, is developing an innovative method to extract copper from ores that are currently too costly or complex for traditional mining techniques.

In January-November of this year, Ukraine’s metallurgical enterprises increased their revenues from ferrous metal exports by 18.06% year-on-year to $2 billion 872.572 million.

PJSC Dniprovsky Metallurgical Plant (DMZ), a part of DCH Steel of DCH group of businessman Oleksandr Iaroslavskyi, reduced production of rolled products by 57.3% in January-November this year compared to the same period last year – to 42.9 thousand tons.

Although Vale is the leader in high-quality iron ore, we have a lot of flexibility in our operations. We need to succeed even when margins are nonexistent and when customers demand cheaper products

Singapore’s Meranti Green Steel plans to build a green steel plant in Thailand, said Sebastian Langendorff, the company’s chief executive officer, in an interview with S&P Global.

Together with other steelmakers in Europe, in recent months we have spoken out on a number of issues that are profoundly affecting our ability to competitively produce steel in Europe today:

Ruukki Construction, part of SSAB, is today celebrating the opening of the new roof profile production line in Vimpeli, Finland. The production line for Ruukki Classic®, Ruukki Classic® LowCarbon and Ruukki® Trendic profiles is the largest single machine investment in the project announced in December 2021. The improvements will result in new, better and more sustainable roofing products more efficiently for Ruukki's installation partners as well as for house builders and renovators. In Scandinavia, the residential roofing range is marketed under the Plannja brand.

Recent years have seen Ruukki invest a total of EUR 8 million in the Vimpeli plant as part of its multi-year investment program. In Vimpeli, the company has further improved product properties, streamlined material flows, increased production capacity and the degree of automation, upgraded production lines and improved social and civil defence shelter facilities at the plant. New equipment investments and layout changes will also improve the safety of processes and the whole plant.

"Our multi-year investment program is nearing completion. We can be proud of the long-term work we are doing to accelerate the green transition in construction by developing both our operations and our product portfolio. Sustainability is a choice. Together with our customers, we can reduce construction industry emissions - one roof at a time," says Sami Eronen, President, Ruukki Construction.

Most advanced technology on the market

The almost 100-meter profiling line completed in Vimpeli is one of the most advanced in the world and will double production capacity of the plant’s snap lock roofing. Customers will receive both new and upgraded products more efficiently and there will be less waste. Product sustainability will also increase as a result of energy efficiency improvements at the plant. These include switching to fossil-free electricity and using recycled packaging materials as part of production.

"We are now ready to serve our customers even better. The new, more automated production line will increase the plant's efficiency, which will be reflected in delivery speed and reliability all the way to the customer. In addition, it enables new, lower-emission products," says Jorma Korhonen, Business Director, Roofing Finland at Ruukki Construction.

Product improvements and new features

In addition to the technically and visually premium Ruukki Classic and low-emission Ruukki Classic LowCarbon standing seam roofing, the production line will also produce new types of Ruukki Trendic roofing with a more affordable coating. The maximum length of the profiles manufactured will increase to up to 14 meters. In addition, new features have been introduced to make product installation easier and improve the appearance.

In standing seam roofing, the structure of the fastening strip has been improved to make the profile move more smoothly, especially on wooden battens, and to better control the thermal expansion properties of the profile. A new microprofiled version of the roofing will be launched. This new product will also help to curb the deformation caused by thermal expansion. Improvements made to both the seam structure and eave bending, on the other hand, will make it easier to install the profile, especially in renovation projects where the eaves may not always be straight. Ruukki Classic is the only standing seam roofing on the Finnish market that has a Eurofins certificate for the waterproofness of the seam. Ruukki Classic’s seam structure has been proven to be one hundred percent watertight up to a roof pitch of 1:9. It is therefore the only snap lock roofing on the market that can be successfully installed on low pitched roofs.

September reported a 6.7% year-on-year decrease, a less sharp fall than July’s 10.8% y-o-y decrease.

In August a poll by economic research firm ifo Institute reported 43% of companies in the sector predicted a decline over the next six months from an already modest level of business activity. Half of the respondents expected business to remain flat.

European steel hot-rolled coil prices were broadly steady on Tuesday December 3, with the market awaiting the outcome of long-term contract negotiations between mills and end users, sources told Fastmarkets.

The Brazilian foreign trade authority, SECEX, reported that the percentage of the total quotas of 529,113 mt were used by the importers until November 25.

The USW said in a statement released Thursday that Mori's goal "is to close the transaction, not preserve our industry or our jobs." Nippon Steel sent the letter in response, saying that the USW's claims are not true.

The process of building an ore bed is a complex task; each bed undergoes months of planning and several weeks of detailed construction in order to create an optimized ore blend suitable for sintering and furthermore blast furnace consumption.

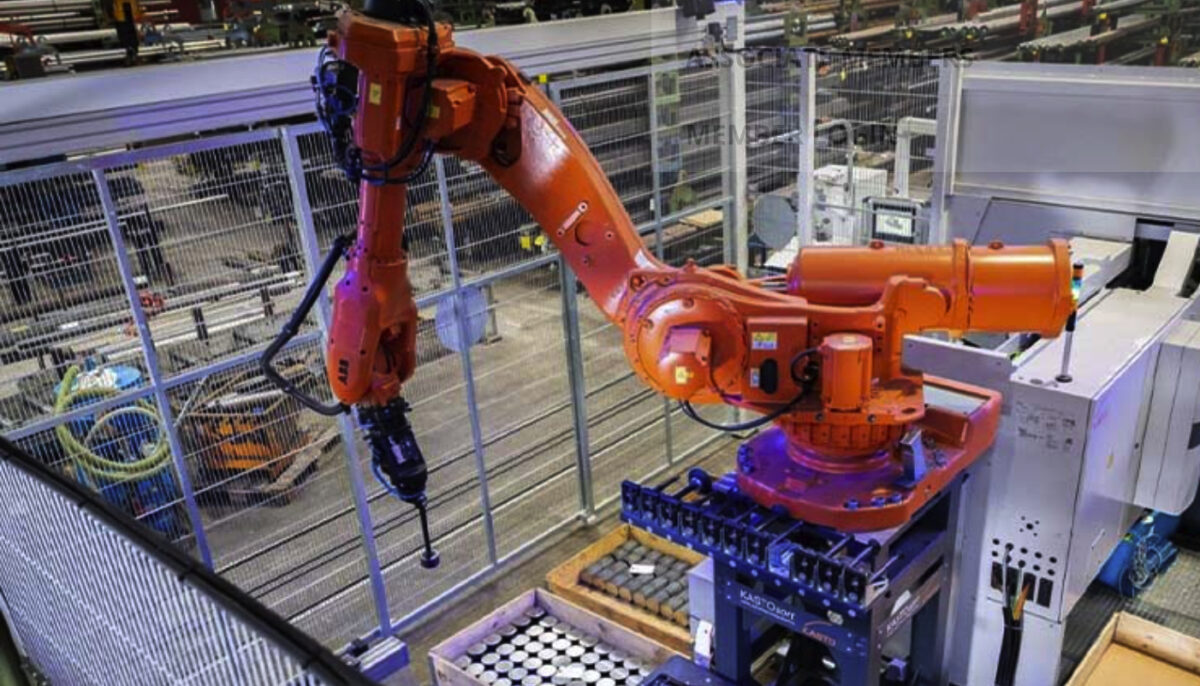

The investment is part of British Steel’s strategy to support the supply of rails to Network Rail, ensuring there is stock ready, as and when required, for its supply chain.

Tata Steel Netherlands and Ecolog are exploring the import of liquid hydrogen and the export of liquid CO2.

The partnership was formalized as part of a working visit by His Majesty the King and Minister Hermans.

The shipment of ferroalloys is kept at minimum levels after the restart of part of the capacities

India's finished steel imports during April-October surged to a seven-year high at 5.7 million metric tons, according to provisional government data reviewed by Reuters on Wednesday.

ArcelorMittal and China Oriental Group have announced a joint venture targeting the growth of electrical steel production, a move set to strengthen their foothold in the burgeoning sector.

The plate market in Poland is quite stable with an average volume over the last 10 years of 1.06 million tons, which is similar to 2023 numbers. The plate market accounts for 8% of total steel consumption in Poland.

Steel production for the month amounted to 603.8 thousand tons, which is 1% less than in September this year, and pig iron production amounted to 624.9 thousand tons (+0.1% m/m).

Nippon Steel, Japan’s top steelmaker and the fourth largest globally, agreed to buy US Steel in December but faced opposition from a powerful labour union as well as from Trump, and President Joe Biden, among others

ANDRITZ Metals is – via the Schuler Group – one of the world’s leading suppliers of technologies, plants and digital solutions in metal forming.

Tata Steel’s UK operations reported revenue of £600 million ($779m) during the second quarter of fiscal 2025, while Ebitda loss stood at £147m. Liquid steel production was 390,000t, while deliveries were at 630,000t.

An initial investment exceeding US$ 600 million, the state-of-the-art facility will supply high-quality iron ore for production of pellets and briquettes in the region