A significant milestone has been reached in the ongoing collaboration between SMS group and Habaş A.S. The integration tests of the automation system for the key components of the project, including the continuous galvanizing lines 1 and 2, the skin pass mill, and the recoiling and inspection line, have just been completed. These tests mark the next step forward for Habaş A.S. to enhance its steel production processes, following the successful integration testing of the pickling-line/tandem cold mill and the training of its personnel in 2023. The project, which has progressed steadily over the past year, underscores the commitment to technical excellence and efficient project management shared by both entities.

Habaş A.S., located near Izmir, Turkey, continues its stride towards modernization and expansion. Following the project start of the pickling line/tandem cold mill (PLTCM) in October 2021, Habaş progressed with the next phase of their partnership with SMS group in April 2023 when the second part of the contract package came into force and marking another significant milestone in their longstanding collaboration. With the new facilities, Habaş intends to expand its manufacturing capabilities in cold strip production considerably and strengthens its own market position. The pickling-line/tandem cold mill (PLTCM) will already reach the installation phase by August 2025. In order to optimize the cold strip properties and product qualities, Habaş has ordered from SMS group an offline skin-pass mill, two continuous galvanizing lines (CGL1 and CGL2), a recoiling and inspection line (RCL) and a tension leveling line. This enables Habaş to produce a large spectrum of advanced steel grades, including, for example, deep drawing material and high-strength grades.

Digital commissioning of automation with X-Pact® Plug & Work integration test

In order to perform the X-Pact® Plug & Work integration test for Habaş, SMS group set up the entire automation system for the customer-specific plants in its test field in Mönchengladbach, Germany and connected it to the plant and production simulation. The digital twin of the integrated plant, developed in parallel with the engineering process, was brought to life during the Plug & Work test by integrating simulation data. The digital twin is subsequently further enriched with online data from the real plant in order to increase its value.

Haşim Ayten, Plant Manager at Habaş, emphasizes the importance of this step:

“The Plug and Work integration test provided us with an invaluable opportunity to ensure all automation systems functioned seamlessly before installation. The realistic simulations and thorough testing allow us to confidently proceed with the commissioning, knowing that our systems are optimized for efficiency and reliability.”

With the X-Pact® Plug & Work test, the original hardware and the software for the customer-specific plants are tested, pre-optimized in the test fields as a complex unit. This saves Habaş valuable time and enables faster ramp-up, very high product quality from the beginning and a ready-made stable production environment.

Plant technology

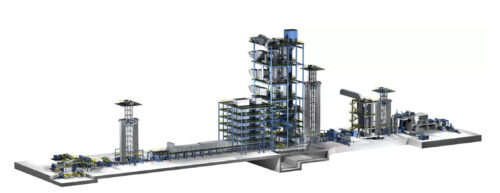

Pickling line / tandem cold mill (PLTCM)

The five-stand pickling line/tandem cold mill is expected to be installed by August 2025. Equipped with SMS group’s latest turbulence pickling technology and a scale breaker, the line ensures an annual cold strip production capacity of 1.65 million tons. The tandem cold mill, featuring CVC® plus technology and an enhanced shifting system, guarantees excellent cold strip tolerances and flatness. With the capability to handle strips as thin as 0.20 millimeters and widths ranging from 700 to 1,980 millimeters, it offers flexibility in production. The carousel reel features the new revolving reel mandrel support bearing, ensuring safe winding of rolled cold strips, even for high-strength grades, which require coiling under high strip tension. The PLTCM allows for flexible production processes and can operate in fully continuous or batch mode.

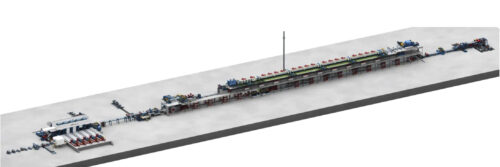

Offline skin pass mill

The offline skin pass mill (SPM) is designed to process hot and cold rolled coils to meet market demands. With an annual capacity of 0.65 million tons, it offers flexibility to handle various coil types, including cold rolled, annealed, hot rolled, and pickled coils. Depending on the incoming material, the skin pass mill can process strips with widths ranging from 965 to 2,100 millimeters and thicknesses between 0.25 and 4.0 millimeters. As the main task of skin passing is to elongate the strip, the maximum value to be achieved is 1.2 percent.

The skin pass millis designed as a four-high mill, featuring work roll shifting and bending to achieve the required strip properties. Equipped with a wet skin-passing system, it ensures strip elongation while maintaining moisture control through the exit-side blow-off dry strip system (DS system), ensuring the strip being coiled on the tension reel is as dry as possible.

The skin pass millis fully equipped with entry and exit side equipment, as well as auxiliary and ancillary systems, to ensure reliable and efficient operation.